The demand for high-quality PCB fabrication and assembly has risen, leading to the development of numerous PCB manufacturers throughout the world. The diversity in kinds of circuit boards, such as flexible PCBs, rigid-flex circuit boards, and high-density interconnect (HDI) PCBs, caters to the different requirements of markets ranging from customer electronics to telecoms.

A printed circuit board is essentially a thin board made from a non-conductive product, such as fiberglass, to which paths and links for electronic components are printed or etched. Their design and assembly are important, and companies that focus on PCB assembly often give a variety of services consisting of prototyping, production, and assembly of these essential components. By utilizing innovative PCB manufacturing strategies, manufacturers can creating circuit card that meet the rigorous needs of high-frequency applications, such as those discovered in superhigh frequency (RF) communication circuits. This consists of the experience to design and produce high-frequency PCBs that can manage the complex characteristics of RF circuits, an important facet of today's communication modern technology.

The process of PCB assembly typically includes numerous vital stages, including soldering components to the PCB, screening for top quality assurance, and making sure the last item meets both regulative criteria and consumer specifications. In a lot of cases, manufacturers make use of surface area place technology (SMT) to guarantee precise positioning and soldering of little components onto the board. SMT components are often chosen because of their effectiveness in terms of area and efficiency. Furthermore, the increase of quick turn PCB services has actually dramatically lowered the preparation for manufacturing circuit boards, enabling companies to introduce faster and bring items to market quicker. This responsiveness to market need is necessary in today's affordable landscape.

The capacities of manufacturers have actually expanded to include not only conventional PCB assembly however additionally custom PCB remedies, allowing organizations to bring their special designs to life. Custom PCB fabrication services allow customers to specify the accurate measurements, layer matter, and products required for their project, making sure compatibility with an array of electronic designs.

Flex PCBs, or flexible printed circuits, stand for an additional specialized location within the PCB sector. These boards can flex and turn, making them excellent for applications where room is minimal or where traditional rigid boards may not fit. The advancement of flexible PCB innovation has opened up new opportunities in item design, specifically in mobile phones, wearable innovation, and medical gadgets. Flexible circuit boards usually feature the benefits of lightweight construction, reduced room demands, and the capability to integrate several functions within a single device, making them a prominent choice amongst designers and developers.

In addition, the manufacturing of multilayer motherboard, which makes up several layers of circuitry stacked with each other, has actually become significantly prevalent. These multilayer boards are crucial for complicated electronic gadgets that require a high level of combination and density. Effective multilayer PCB assembly demands exact alignment and cautious factor to consider during the design stage to stop signal interference and make sure optimal efficiency. The obstacle of building top-tier multilayer circuit card usually lies in producing vias-- small layered openings that permit electrical connections in between the different layers. Advanced methods, like blind and buried vias, have actually arised to meet these complexities without jeopardizing the performance and capability of the PCB.

One more crucial factor to consider in PCB engineering is impedance control, which is important for making sure signal stability, particularly in high-speed applications. Designers need to very carefully examine the physical layout of circuit traces, the material buildings of the PCB, and the link strategies to preserve constant impedance across the board. Integrating these concepts right into PCB design not only improves performance but additionally adds to the dependability of communication circuits and high-frequency applications.

For companies seeking to improve their PCB production process, turnkey PCB assembly services can be a perfect solution. These services envelop all stages of production from fabrication to assembly and testing, under one umbrella. This strategy not just minimizes the moment needed to turn design concepts right into completed products however also streamlines supply chain administration by reducing the demand for several suppliers. The capacity to acquire all components and assembly services from a single resource enhances performance and can result in cost financial savings, especially for high-volume production needs.

The competition among PCB manufacturers has actually led to an increased emphasis on quality and advancement, with several firms carrying out strenuous quality control procedures to guarantee their circuit boards satisfy market criteria. Certifications like IPC-A-610, which regulates the reputation of electronic assemblies, play a critical function in guaranteeing consumers of the integrity and resilience of their items. Manufacturers must depend on advanced assessment modern technologies, such as automated optical inspection (AOI) and X-ray analysis, to spot problems early in the production process, thus decreasing waste and improving general product quality.

The ecological influence of PCB production has additionally come to be a substantial worry in recent times. As services end up being a lot more ecologically mindful, PCB manufacturers are adopting sustainable techniques, including the use of environmentally friendly materials and the execution of waste decrease efforts. Additionally, regulations pertaining to the disposal of electronic waste, such as the European Union's RoHS instruction, have influenced manufacturers to decrease making use of dangerous materials in their items, fostering an industry-wide change toward greener production methods.

In the realm of technology, current innovations in PCB technology have introduced exciting opportunities. As electronics proceed to evolve, so as well does the value of cutting-edge approaches to PCB design and manufacturing.

Small-scale prototyping has likewise progressed dramatically, enabling companies to test designs rapidly before committing to larger production runs. Prototyping not only allows engineers to identify potential design defects yet additionally supplies a possibility for optimization, allowing customized adjustments that can make a considerable difference in the final efficiency of an electronic tool. The ability to provide premium prototypes in a short timeframe enhances the fast speed of product growth that identifies today's innovation landscape.

As demand for electronic devices remains to intensify, the need for advanced PCB remedies will just grow. The rich variety of PCB designs, ranging from circuit card assemblies to specialized high-frequency designs, underlines the critical function that these boards play in enabling the capability of contemporary electronics. With ongoing innovations in manufacturing modern technologies, flexible designs, and material scientific researches, the future of PCB production looks appealing. Continued partnership between manufacturers, developers, and end-users will certainly be vital in driving the future generation of developments that will certainly shape the electronic landscapes of tomorrow.

Finally, from the fundamental motherboard to the highly sophisticated multilayer designs and flexible read more circuits that adjust to cutting-edge applications, printed circuit boards represent the core of electronics. The convenience, reliability, and efficiency of these components continuously drive sectors to seek exceptional abilities in PCB manufacturers. With the most recent advancements in innovation, the production of PCBs is ending up being extra reliable, environmentally friendly, and tailored to the progressing needs of an increasingly electronic globe. As we look ahead, the integration of new materials, designs, and fabrication techniques will unquestionably play an essential function in transforming exactly how we communicate with innovation, leading the way for innovative electronic applications in the years to come.

Mara Wilson Then & Now!

Mara Wilson Then & Now! Julia Stiles Then & Now!

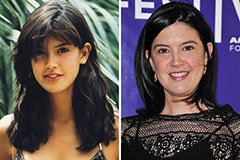

Julia Stiles Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!